Normalizing Services

Advantages of Normalizing

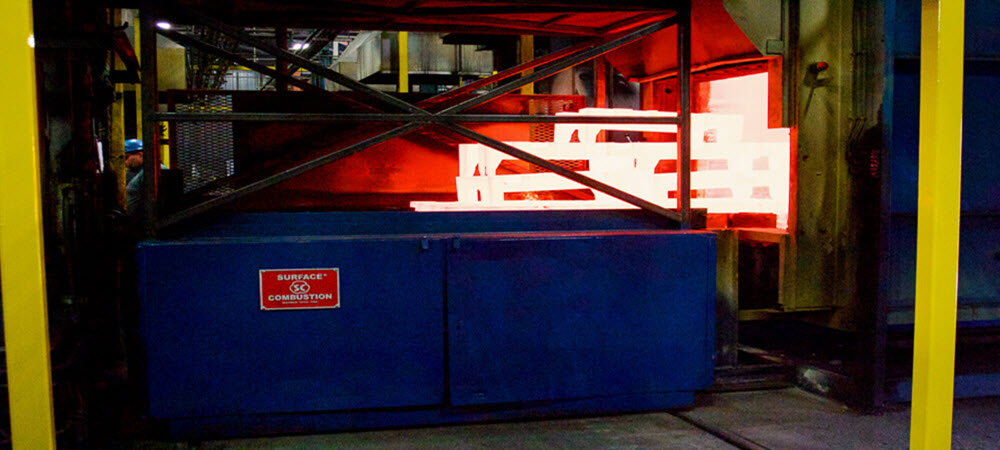

The normalizing process is often referred to as a homogenizing treatment where the component is heated to an elevated temperature and then allowed to cool to room temperature. The process produces a uniform microstructure. This improved uniformity is beneficial to both machining and subsequent heat treating.

Precision Thermal Processing has multiple normalizing furnaces that can process loads up to 20,000 lbs. and component lengths up to 144.”

Components Which Benefit From Normalizing

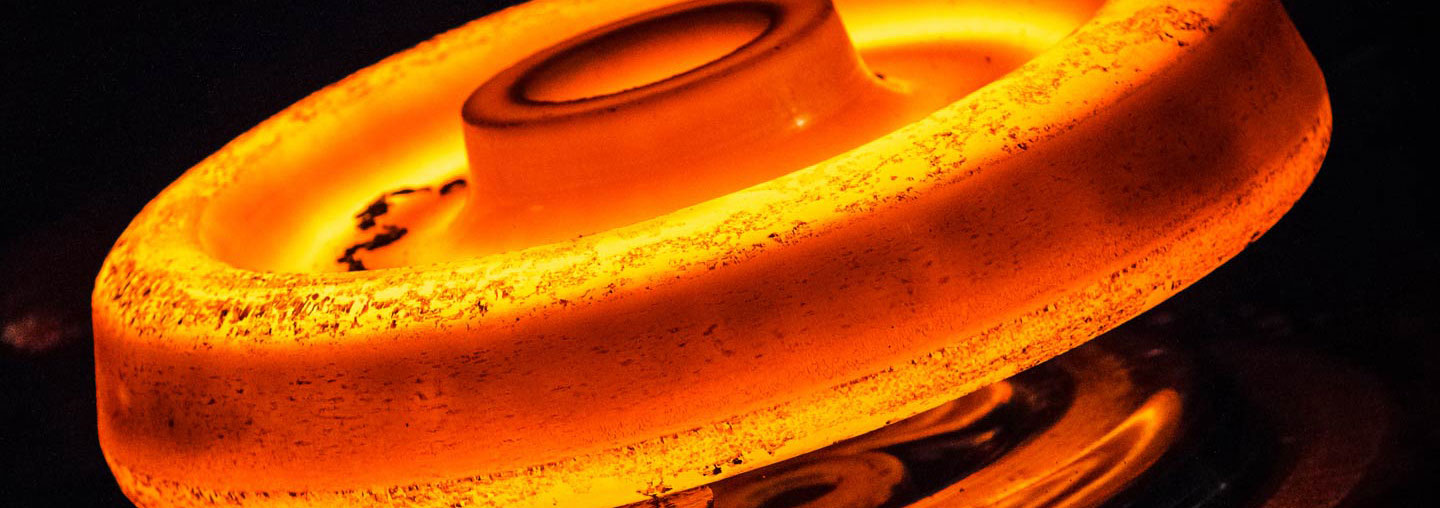

- Forgings

- Castings

- Gears / Pinions

- Pistons

- Valves & Valve Seats

PTP’s focus on engineered solutions, combined with ISO 9001 and ISO 17025 accreditations, makes us the preferred vendor for normalizing. Contact us to learn more about Precision Thermal’s Normalize cycles.