On Site Metallurgical Services

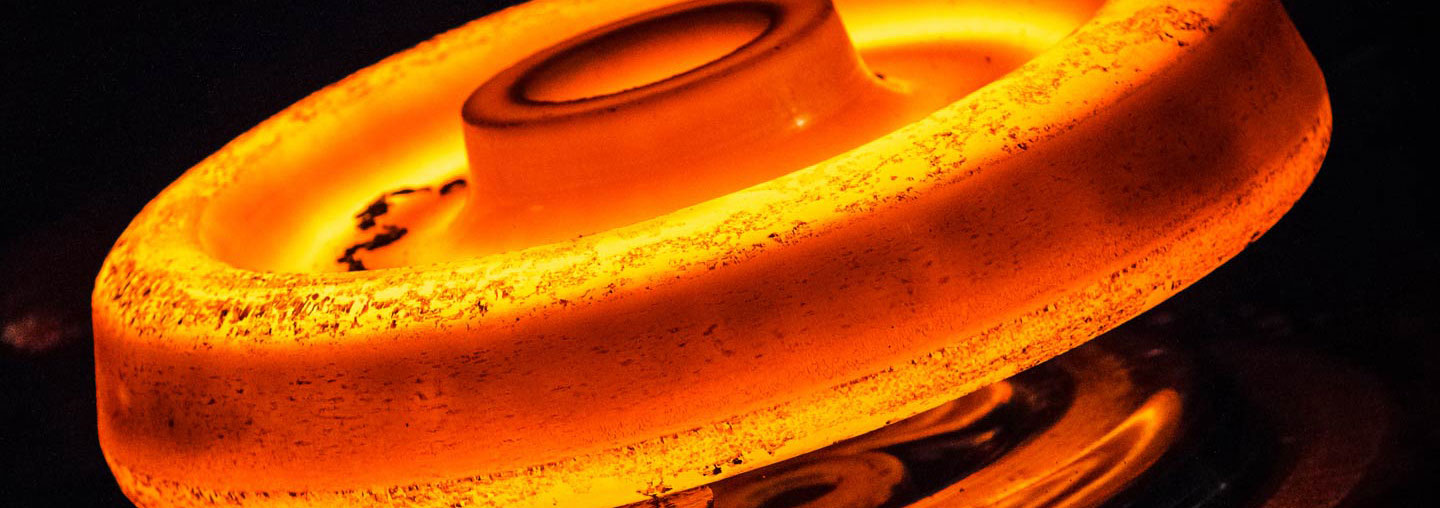

From construction and transportation to food cultivation and energy generation, metals play a pivotal role in modern societies. Analyzing the behaviors and properties of metals enables manufacturers to understand their performance capabilities in certain situations better.

Take your application to new performance levels with metallurgical analysis services from Precision Thermal Processing. We’re an ISO 9001:2008 and 17025-accredited metallurgical testing laboratory that specializes in the analysis and validation of metals and metal alloys.

ISO/IEC 17025:2005 accredited by A2LA

View more about our testing services below

Metallography

Image Analysis System:

- Grain Size Measurement

- Microstructure

- Constituent Ratios

- Distance/Depth Measurement

- Case Depth

Failure Analysis:

- Crack Evaluation

- Micro-structural Defect Analysis

Micro-structural Analysis:

- Grain SizeDetermination

- Heat Treat Condition

- Microstructural Constituents

- Inclusion Rating

Macro-Etch Testing:

- Grain Flow Analysis

- Center Soundness

Mechanical Tests

Tensile, Yield, Reduction of Area and Elongation:

- CNC-Machined Samples

- Round Bar or Flat

- Ambient Temperature

Charpy V-Notch Testing:

- Ambient

- Cryogenic Temperatures

Hardness Testing:

- Rockwell

- Brinell

- Superficial

- Vickers and Knoop

Chemical Tests

Optical Emission Spectroscopy:

- Carbon and Alloy Steel

- Tool Steel

- Stainless Steel

Carbon and Sulfur Combustion Analysis:

- CNC Machine Chips

- Shim Stock

Precision Thermal Processing offers professional services with a sense of urgency expected by our customers. We have an on-site fully equipped lab and a dedicated staff focused on providing our customers with timely results. Get in touch to learn more about our services.

What is Metallography?

Metallography is the study of the physical structure of metals and metal alloys using microscopy. The knowledge obtained from metallography is used in the design, development, and manufacture of alloy materials. Using advanced equipment, we provide a full suite of examinations. Mechanical tests evaluate materials under conditions such as tension, compression, and temperature.

Precision Thermal Processing is equipped to provide a comprehensive range of mechanical testing services for metals and alloys with quick, reliable results. Chemical tests involve an examination designed to identify, quantify, or characterize a chemical compound or chemical group. Chemical testing is vital for regulatory compliance and to understand the quality and composition of chemical substances and materials used in industrial processing and manufacturing. At Precision Thermal Processing, we offer a range of chemical testing techniques.

What is Metallography used for?

Metallurgical analysis reveals the condition and makeup of materials, which helps determine whether they can perform safely and optimally. Understanding how the metal reacts when transformed from the raw material into a finished part improves performance and quality while reducing development time, costs, and risks to humans and the environment. Precision Thermal Processing has an in-house, state-of-the-art metallurgy laboratory staffed by highly trained technicians who specialize in the testing of traditional metals and advanced alloys. Results help clients across an array of industries evaluate the integrity of metals as well as pinpoint failure.

- Agriculture

- Construction

- Energy

- Power generation

- Tool and die

- Transportation

The core of our testing processes is the ability to identify and validate materials. We provide certified reports that detail traceable and repeatable documentation showing the testing performed and data obtained. Housed in a 60,000-square-foot facility, our laboratory can analyze test specimens of any size. We offer a range of metallurgical testing services.

Work with us

Ensure materials are suitable for their intended use with reliable metallurgical testing services from Precision Thermal Processing. With an unwavering commitment to quality, we’re your materials, testing provider. Our metallurgical testing services can support you at any stage of production, such as assisting with product research and development, resolving manufacturing process quality issues, analyzing failures, and confirming regulatory compliance.