Surface Treatments

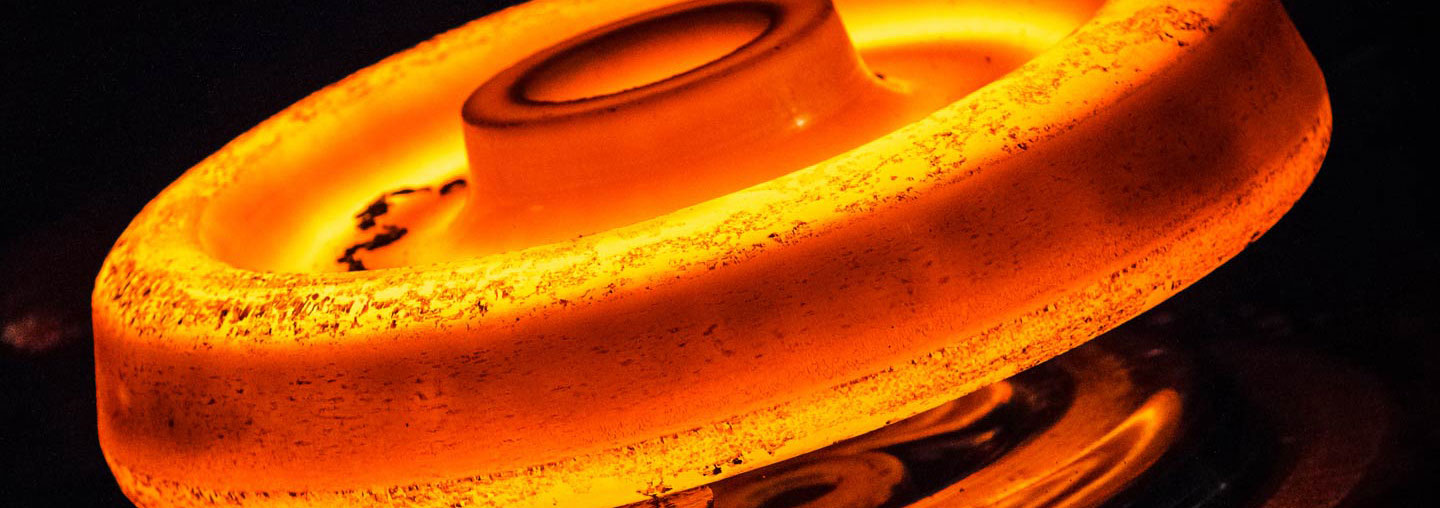

1: Carburizing Process

Carburizing is one of the oldest and most effective ways of producing a hard surface layer while maintaining a ductile core. Although the process may be old, the equipment used to accomplish this hardening is extremely sophisticated. The furnaces are capable of temperature uniformity of + or- 10F. The carbon content of the furnace atmosphere is digitally controlled and programmable for optimal results and repeatability. We offer carburized depths up to 0.150".

PTP’s focus on engineered solutions, combined with ISO 9001 and ISO 17025 accreditations, makes us the preferred vendor for carburizing surface treatments. Contact us to learn more about our carburizing capabilities.

Types of Components Processed

- Gears / Pinions

- Wear Plates

- Shafts

- Valve Seats

2: Boronize Process

This is a highly specialized process where Boron is diffused into the surface of the component. Results can be achieved on selected areas or over the entire surface of a component. Hardness in excess of Rc70 is typically achieved. This process is best suited to combat abrasive wear. Because of its highly technical nature, we recommend discussing your application and material selection prior to manufacturing.

Contact us to learn more about Precision Thermal’s Carburizing and Boronizng capabilities.

Typical Applications

- Agricultural Wear Parts

- Hand Gun & Rifle Components

- Oil & Gas Components

- Valve Seats