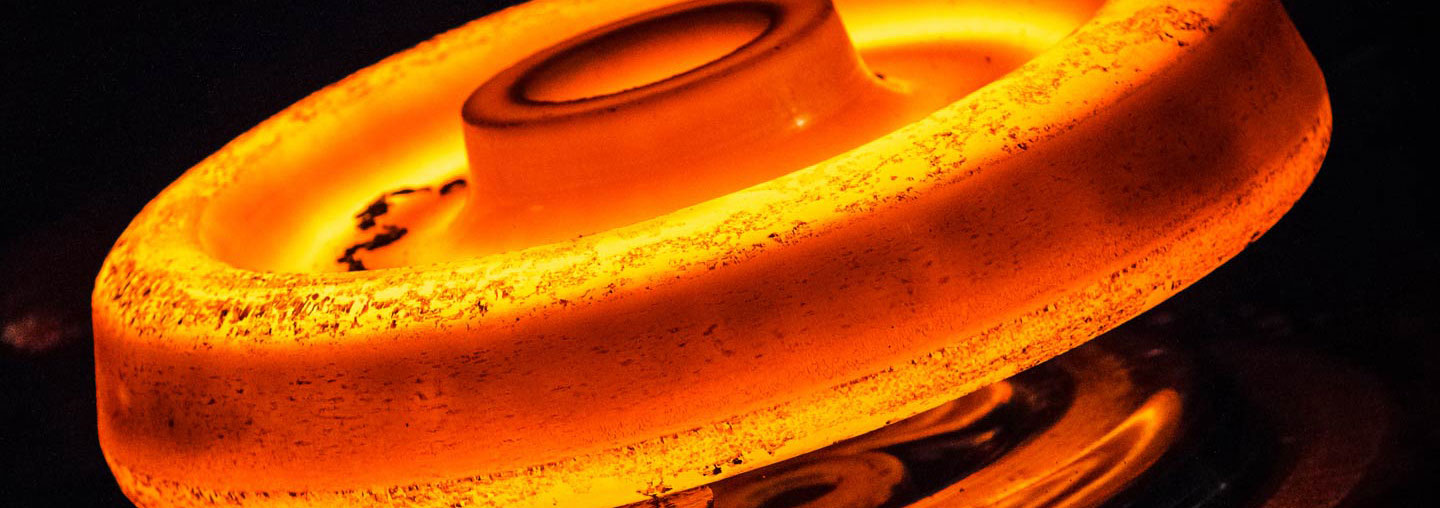

Metal Stress Relieving Services

What causes Residual Stress in Metal?

Residual stresses may remain in a material after the original cause of the stresses has been removed. The residual stresses are a result of the material being stressed beyond its elastic limit and thereby causing plastic deformation. Some examples are: Non-uniform deformation during heating or cooling, non-uniform deformation during mechanical processing and phase transformation during cooling.

How Do We Alleviate This Type Of Stress?

Detrimental stresses can be controlled through stress relieving. This is accomplished by placing the component in a furnace either with or without a protective atmosphere, and then heating to a predetermined temperature. The component is held at the appropriate time and temperature sufficient to relieve the stresses so it can be machined with a minimal amount of distortion.

Components Which Commonly Benefit From Stress Relieving

- Castings

- Weldments

- Shafts

- Flame Cuts or Burnouts

- Rolls

PTP’s focus on engineered solutions, combined with ISO 9001 and ISO 17025 accreditations, makes us the preferred vendor for stress relieving heat treating. Contact us to learn more about Precision Thermal’s Stress Relieving capabilities.