Metal Hardening Services

What is the Hardening Process?

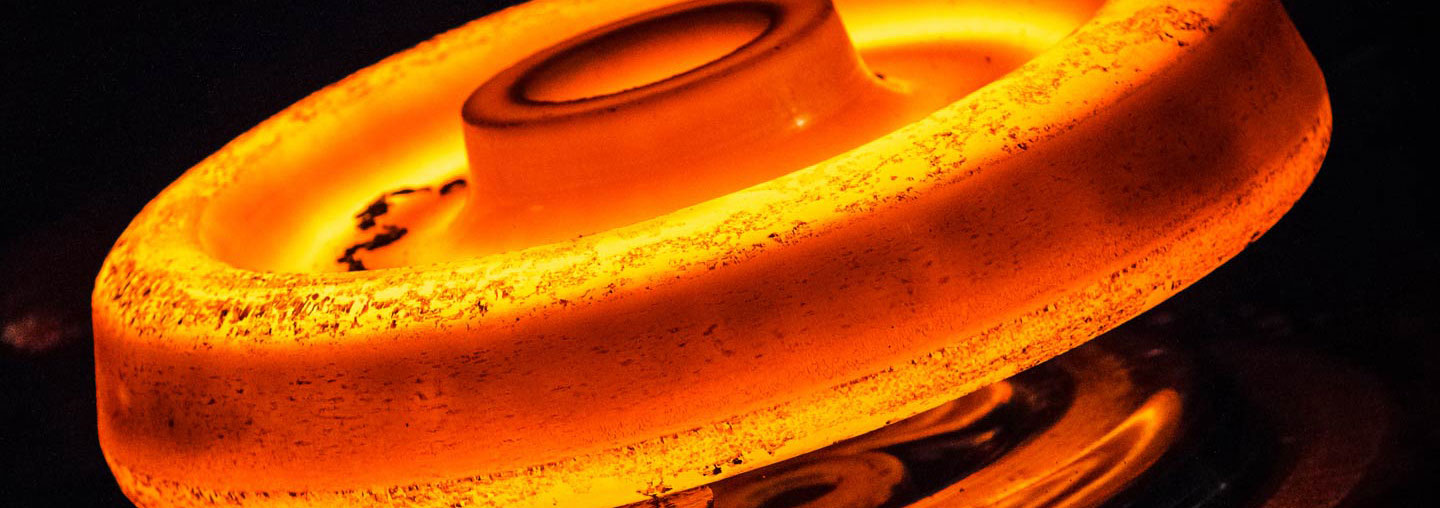

The Hardening Process for most components is accomplished by heating to a temperature that changes the part’s microstructure. After sufficient heating, the part is quenched in a liquid, which results in a greater hardness and improved mechanical properties. Case hardening is where the metal surface is reinforced by adding a more durable metal alloy to the surface.

We utilize advanced heat treating equipment to provide consistent case hardening services for a number of alloys. Some of these materials include:

- Carbon Steel

- Alloy Steel

- Ductile Iron

- Tool Steel

- Stainless Steel

Typical Applications Include:

Precision Thermal’s Hardening furnaces are capable of processing parts up to 72” in length, with load sizes up to 6,000 lbs. PTP’s focus on engineered solutions, combined with ISO 9001 and ISO 17025 accreditations, makes us the preferred vendor for hardening services. Please contact Precision Thermal to learn more about our metal hardening services.

- Shafts

- Brackets

- Pistons

- Valves

- Gears